A built up roof system is a popular choice for buildings with low-slope or flat roofs. Often referred to by the acronym BUR, this system has been used for 100-plus years in the U.S.

What makes BUR systems so popular?

They are known for providing excellent protection due to their redundant nature because they are made up of multiple layers of ply sheets and asphaltThese layers are then topped off by a cap sheet or a flood coat of asphalt and granules. The multiple plies provide resistance to weather and heavy-duty protection for the building.

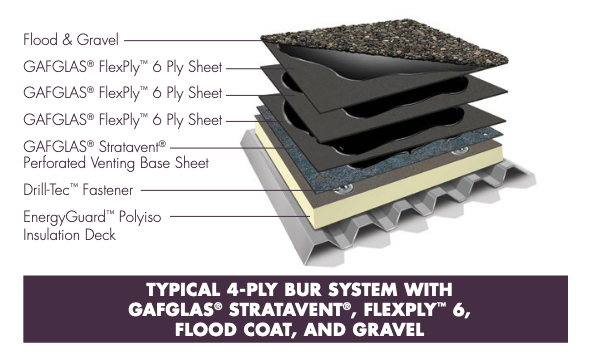

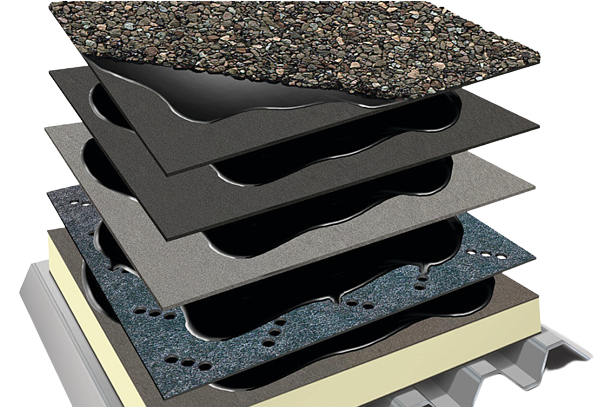

Components of a Built Up Roof System

Built up roof systems can be constructed in a variety of ways.

Often, the built up roof system starts with a base sheet installed over the polyisocyanurate insulation or cover board, typically through the use of mechanical fasteners.